- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

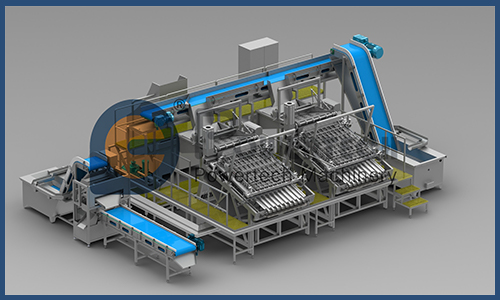

Shrimp Peeling And Deveining Machine is a kind of shrimp processing machine Powertech designed for automatic processing shrimp instead of manual processing. It has the function of back cutting, deveining and peeling of head-off shrimps automatically and processing into different styles, which processing much faster than manual processing, so it brings high profitability to processors because much higher capacity, and lower energy consumption as well as much lower manual cost.

Shrimp processors can choose suitable units of Shrimp Peeling And Deveining Machine according to their capacity requirements, and start suitable units of Shrimp Peeling And Deveining Machine according to their real order capacity requirement. Normally, every 6 units of Shrimp Peeling And Deveining Machine can form a production line, it’s very flexible for shrimp processors.

Shrimp Peeling And Deveining Machine is very easy to be operated, the operator just need to put shrimps into the infeed trays on the machine one by one, and make the last segment of the shrimp flush with the black line on the tray, then shrimps will be cut at the back, vein will be removed and shell will be removed automatically. When process shrimps of different sizes and different styles, it’s very easy to adjust machine because there are scale marks on the parts that should be adjusted. The whole operation is very safety and hygiene, and the machine is multifunctional and stable, convenient to be maintained.

The working principle of Shrimp Peeling And Deveining Machine is to use mechanical principles to clip the tail of shrimp, and then get the back of the shrimp to be cutted by blade, vein is cut off at the same time, then vein be removed by water and brush, after that, the abdomen part of shrimps be poked by niddles and then shell be removed by pulling off.

Shrimp Peeling And Deveining Machine has the multifunctional technology that could process various kinds of shrimps, such as Vannamei, Argentina Red Shrimp, Black Tiger Shrimp, Brunei Blue Shrimp and other some kinds of sea caught shrimps. And it also has the multifunctional technology that could process head off shrimps into 7 different processing styles, such as PDTO, Butterfly, EZ Peel, PD and etc. It could also process head on both raw and cooked shrimps, get the shrimps include head part cut.

Traditional shrimp processing factory should employ a lot of workers for the process of back cutting, deveining and peeling of raw shrimps. With continuous processing capacity expansion and labor cost rising, more and more shrimp processors apply automatic peeling instead of manual peeling. Because compared with traditional manual peeling, our Shrimp Peeing And Deveining Machine has following advantages:

Faster : Peeling speed is 6 to 10 times than manual operation, ensuring high efficiency;

Better : Better consistency of end products and reduces human error;

Lower : Less labor and lower cost. Smaller footprint for shrimp peeler, which reduces workshop construction budget and running cost;

Safer : Less contact between human and products, shorten processing time while ensuring freshness and food safety;

Smarter : Smart production plan. Start suitable quantities of peelers according to productivity requirement. Less problems with labor source during season and off-season.

We Powertech is dedicated to shrimp and fish processing advanced equipment and total solution for many years, Shrimp Peeling And Deveing Machine is we Powertech developed for shrimp processing under our rich experience in shrimp processing, we have agained 3 innovation patents and 15 utility patents, and our machine quality is Europoean standard, we use high quality food grade 316L stainless materials and many important parts are imported from Europe and Japan.

Restaurant Shrimp Peeling And

Deveining Machine

Restaurant Shrimp Peeling And Deveining Machine is a compact Shrimp Peeling And Deveining Machine We Powertech specially designed and developed for chained restaurants, central kitchen and etc. It is much compact than Shrimp Peeling And Deveining Machine, all the other parts like function, usage, performance and etc are same as Shrimp Peeling And Deveining Machine.

Crayfish Back Cut And Deveining

Machine

Crayfish Back Cut And Deveining Machine is we Powertech designed and developed especially for processing crayfish, because the shell of the crayfish is very hard, so very difficult to get it peeled. Crayfish Back Cut And Deveining Machine could get the back of the crayfish cut easily, thus brings a lot convenience to peeling and deveining.

Automatic Shrimp Peeling

System

Automatic Shrimp Peeling System is our another kind of shrimp peeling machine, it’s a whole production line consists of about 10 equipment with the function of raw material cleaning, deheading, peeling, filtering, water circulation, selecting and etc. It’s for processing both head on and headless shrimps into PUD fully automatically, which do not have the deveining function yet.

Address: No. 8 Yongfu Road, Gangzha District,

Nantong City, Jiangsu Province, China

Phone: +86-400-1390100

Email: info@ptmcn.com